Products

Neo-semitech's products will help maintain optimal production conditions,

which will reduce the loss rate due to equipment errors and increase productivity to make the best production activities for companies.

Our Product

SMST

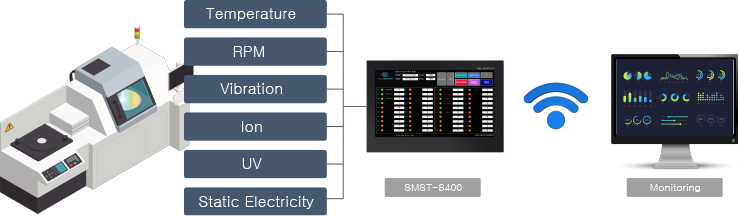

SMST-8400

Multipurpose monitoring equipment with compact and light design allowing maximum 40 channels assures stable operation by measuring diverse data of installation in terms of temperature, vibration, voltage and number of revolutions.

- Realtime transmission to manager via wire/wireless communication

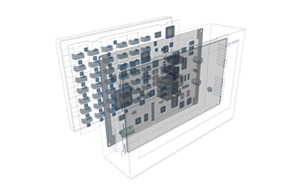

Front Panel

- Compact Size

- Light Weight

- 7”Display

Back Plate

- Digital 20ch,

- Analog 20ch

- Total 40ch

- Wire & Wireless

- Communication

- Multi Purpose

- Sensing

- Flexible

- Compatibility

-

SMST Definition

Monitoring the condition of the equipment by abbreviation of the Smart Multi Sensing Technology

-

SMST-8400 Purpose

Check the abnormalities of the equipment and prevent it in advance.

SMST-8400 Measuring Instrument spec.

| Size(mm) | 180*120*70 (WxDxH) | |

| Operating Voltage | DC 24V | |

| Operating Current | Without Sensor | 1,000mA Max |

| With Sensor | 1,000mA Max | |

| Display | 7” Touch screen | |

| Sensor Type | Temp, UV, ACC, RPM, Ion, PLC, Ext | |

| Number of channels | Digital: 20ch Analog: 20ch | |

| OS | Window | |

| Protocol | Json | |

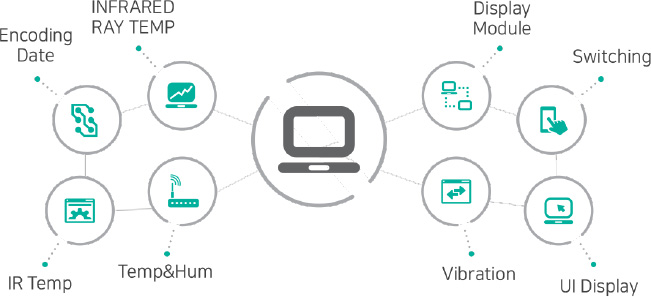

Wireless IoT Sensor & Module

SMST-8400 Function & Effect

Use data collected through various sensors to reduce deviations between equipment to improve production quality.

Alarm can be sent through advance detection of abnormal conditions of the equipment, and actions can be taken before system failure or defect occurs.

Real Time Data Resource System

Connected management of other systems (MES, FDC, SPC) to improve product quality

Customer Quality Satisfaction, Manufacturing Competitiveness

Depending on the communication environment, wired and wireless communication can used

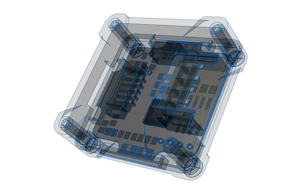

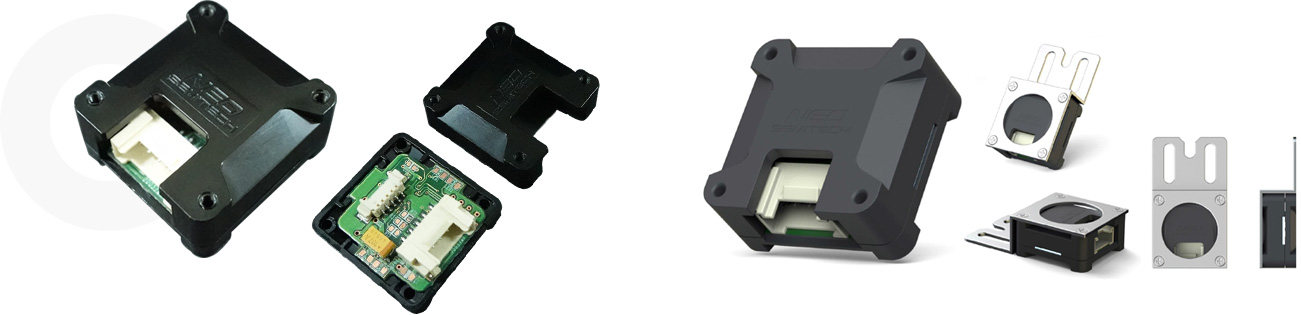

ADC

Analog Digital Converter

It maximizes production efficiency by collecting, analyzing and optimizing information based on sensors, and secures thefield data related to reliability including performance, life and failure rate of equipment.

Analog Digital Converter Pin-Map

ADC Measuring Instrument spec.

| Size(mm) | 27(W)*27(D)*12(H) | |

| Resolution | 16BIT | |

| Supply Range | 5.0V | |

| Low Current Consumption | Continuous Mode | Only lSOμA |

| Single-Shot Mode | Auto Shut-Down | |

| Programmable Data Rate | 8SPS to 860SPS | |

| Internal Low-Drift Voltage Reference | ||

| Internal Oscillator | ||

| Programmable Comparator | ||

Analog Digital Converter

Smart factory core technology is a technology that optimizes the information collected and accumulatedthrough sensors or simplifies the production schedule.

Integrated data system that collects and analyzes data from different types of sensors

Smart factory system that improves manufacturing process efficiency by predicting equipment failure in advance

Obtain field data on the reliability and reliability of equipment performance, lifespan, failure rate, etc.

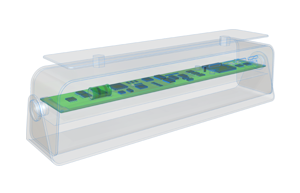

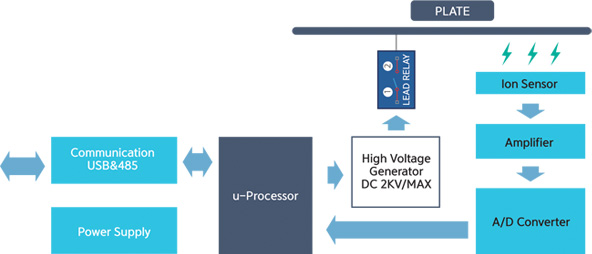

IDT

ION DECAY TIME

It inspects and measures performance of Ion Blower to remove static electricity occurring during semiconductor production, and the small size allows unrestricted measure points and simultaneous measurement of temperature and humidity.

-

Decay Time Definition

Voltage applied to measure attenuation time up to 90%

-

Decay Time Purpose

Check the performance of the ion blower to remove static electricity quickly

Expectancy Effects

Resolve the hassle of a person’s own measuremen

Easy to install at every major point because of its small size

Prevent Quality Losses by ESD

Improve customer satisfaction(reliability) by improving ESD management

Ion Decay Time Measuring Instrument spec

| Size(mm) | 140(W) × 2(D) × 40(H) Controller & Plate lntergral form |

| Operating Voltage | DC 5V |

| Time Range | 0~99.9 Sec |

| Charging Voltage | Start : ±1,000 ~ 3,000 V Stop : ± Start Voltage의 90% Clear point in time |

| Event, Schedule | Can be set based on user criteria |

| Calibration | Always-on calibration and zero adjustment with calibrated reference instruments |

| Communication | USB / RS-485 |

Wireless IoT Sensor & Module

Differention Form Commercial Products

Real time Automatic measurement possible

Compact size & Light Weight

All-in-one type(Plate&controller)

Temp, Hum simultaneously measurement