Business

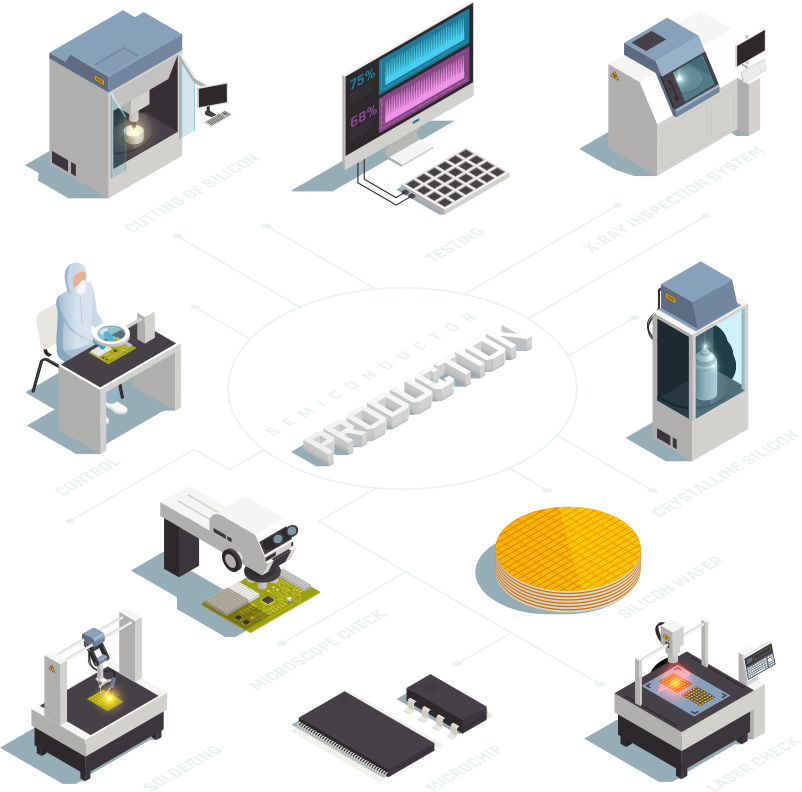

We have focused on semiconductor measuring equipment and semiconductor equipment,

and we will make efforts to create the best value with the best products through continuous research and development and quality improvement.

World’s Best

Global Premium Company,

NEO-SEMITECH

In our fast-changing time, high-tech industries are being diversified and require technological advancement.

Neo-semitech has the passion and ability to predict the future, overcome the limitations of technology, and change our tomorrow even further.

We'll think more, study more, look wider.

Our Solution

Precision Sensing

Detects and analyzes all situations that may occur during the operation of a precise and sensitive semiconductor facility.

Cutting-Edge Technology

Real-time monitoring and control is possible by applying state-of-the-art information and communication technology and next-generation Internet of Things-based wireless communication.

Smart Factory

Lead manufacturing innovation by building intelligent production plants that combine digital automation solutions.

Growth of Production

Stabilization of manufacturing processes improves productivity by facilitating the flow of product production.

Reliability Improvement

A stable product produced in an optimal environment satisfies customers' high performance needs, which can improve inter-company reliability.

Company Growth

We create the future of the company with stable processes and top quality products.

-

Cause

Production processing of diverse conductors and production processing of advanced digital industry constitute a complex and precise production processing stage ranging from warehousing of raw materials to production and examination of finished products.

Despite being the manufacturing installation processing based on high-tech equipment, the equipment operating under the detailed processing is exposed to plenty of unpredictable errors.

-

Process

All our assignment will consist in maintaining product quality and creating high productivity by detecting, monitoring and complementing errors, in the early stage, that occur during the production process in the circumstances of limited workforce and time

-

Result

Our product group monitors the operation status of production installation and carries out realtime transmission it to the manager via wireless communication.

The analyzed measured value helps maintain the optimum production conditions, and this will contribute to bringing the maximum production activities of companies by reducing the loss factor caused by equipment errors and expanding productivity.